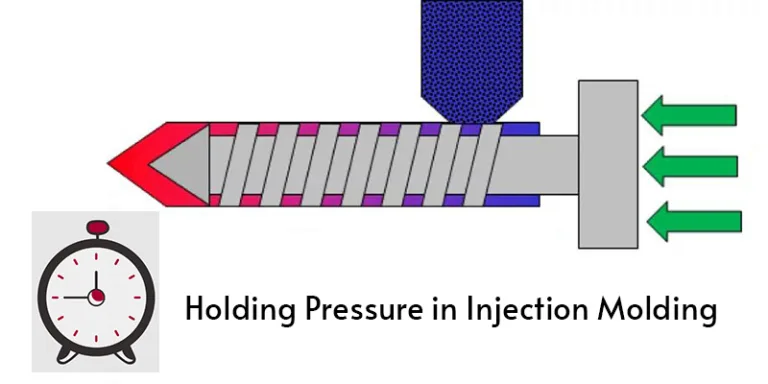

What is rubber injection molding?

Rubber injection molding is a versatile manufacturing process that allows for the production of high-quality rubber parts. By injecting molten rubber material into a closed mold, complex shapes can be achieved with precision and consistency. This process offers advantages such as excellent material properties, reduced wastage, and enhanced design flexibility. It is commonly used in industries such as automotive, medical, and consumer goods.

With our expertise in rubber injection molding, we deliver reliable and customized solutions that meet your specific requirements.