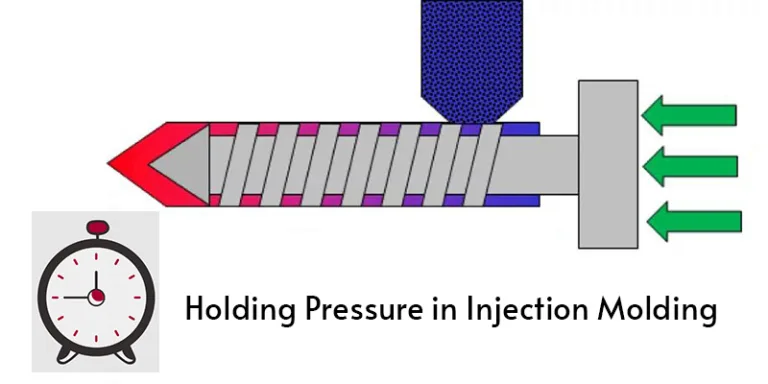

What is injection molding?

Injection molding is a widely used manufacturing process for producing plastic parts. It involves injecting molten plastic material into a mold cavity, which then cools and solidifies to form the desired shape. This process allows for the production of complex and precise parts with excellent repeatability.

Injection molding offers advantages such as high production volumes, cost-effectiveness, and versatility in material selection. It finds applications in various industries, including automotive, electronics, and consumer goods. At [Your Company Name], we specialize in injection molding, utilizing advanced equipment and expertise to deliver high-quality, custom plastic parts. Our dedicated team ensures precision, efficiency, and customer satisfaction throughout the injection molding process.