Urethane cast molding, also known as polyurethane casting, is a versatile manufacturing process that involves pouring a liquid polyurethane material into a mold and allowing it to cure. The mold is typically made from silicone or other materials that can withstand the curing process. Urethane cast molding allows for the production of custom polyurethane parts with exceptional precision and detail. It offers advantages such as flexibility in material properties, quick turnaround times, and the ability to create complex geometries. At X-Mold, we specialize in urethane cast molding, delivering high-quality and durable polyurethane parts for various applications.

Cast molding is a highly versatile manufacturing process that allows us to produce custom polyurethane parts with precision and efficiency. At X-Mold, we specialize in cast molding, offering a range of advantages for your project.

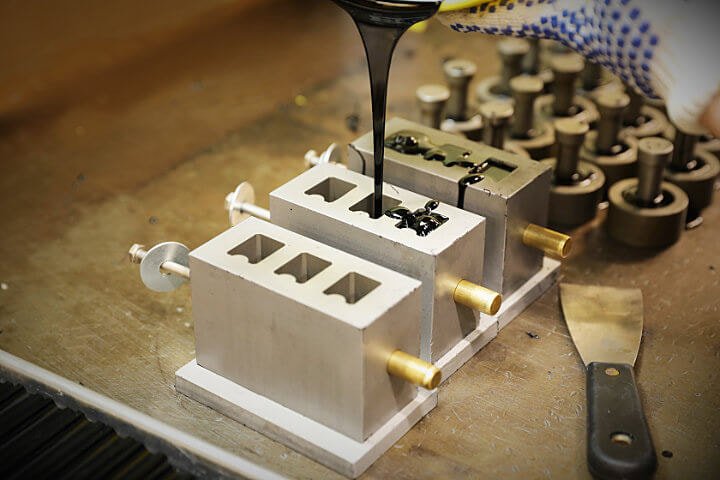

The process begins with the careful preparation of the mold. The mold is designed and fabricated to match the desired shape and specifications of the part.

The polyurethane material is precisely mixed according to the desired properties. The mixed material is then poured into the prepared mold.

The poured material undergoes a curing process, where it solidifies and takes the shape of the mold. This curing period allows the urethane material to reach its optimal hardness and durability.

Once the material has fully cured, the mold is opened, and the part is carefully removed. Finishing touches, such as trimming, sanding, and painting, can be applied to achieve the desired final appearance.

We offer a wide range of material capabilities for cast molding, providing you with the flexibility to choose the ideal material for your project. Our expertise in cast molding allows us to work with various materials, each offering unique properties and advantages.

Make your cast molding parts stand out with our wide selection of surface finishes. Choose from glossy, semi-glossy, matte, and textured options to achieve the perfect look and feel.

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface textture

Enjoy a wide arnge of customization options to meet your unique project requirements.

Benifit from our extensive knowledge and experience in the fielf of injection molding.

We offer competitive priing without compromising on quality or service.

Our team provides personalized support and guidance throughout the project.

Choose from a diverse range of high-quality materials for your injection molded parts.

Our cast molding capabilities extend across numerous industries, offering versatile and reliable solutions for diverse applications. Trust us to provide custom cast molding solutions tailored to your specific industrial requirements

Precision Aerospace Solutions for Quality Parts

Enhancing Farming Efficiency with Custom Agricultural Parts

Precision Automotive Solutions for Quality Parts

Creating Quality Consumer Products for Market Success

Precision Molding for Electronic Innovations

Precision Parts for Safer Healthcare Solutions

Energizing the Future with Innovative Solutions

Common inquiries about our cast molding services. Contact our service team if you have more questions.

Yes, urethane cast molding is ideal for producing prototypes and small quantities, making it a cost-effective solution for testing and market validation before full-scale production.

Lead times for urethane cast molding projects are relatively short compared to other molding processes, typically ranging from a few days to a couple of weeks, depending on the complexity and quantity.

Urethane cast molding is suitable for intricate or complex designs, as the liquid resin can capture fine details, undercuts, and overhangs without the need for complex tooling.

Yes, custom colors and hardness levels can be achieved through urethane cast molding by selecting the appropriate materials and formulations.